WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

pakistan crusher,stone crusher machine,quarry crusher crusher,iron ore crusher,gypsum crusher,cement grinding mill plant, marble grinding ball mill,stone crushing ore ...

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology F.L.

Grinding media. Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill.

Cement Kiln Process Specialist, expert trouble shooter for process problems with cement kilns.

The first step in making concrete is to prepare the cement. One type of cement, Pordand cement, is considered superior to natural cement because ...

CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology Asia-Pacific, Brisbane, Australia e-mail: alex.jankovic@

Cement is a binding agent and is a key ingredient of the most used man-made material: concrete. The demand for cement is strongly correlated to the rate of economic ...

Manufacturing - the cement kiln. Most Portland cement is made in a rotary kiln. Basically, this is a long cylinder rotating about its axis once every minute or two.

We make replacement wear part castings for abrasive and high heat applications in mining, crushing, grinding, and shredding, for industrial clients worldwide.

FEECO Belt Conveyors. FEECO is the premier name in custom conveying systems, including heavy-duty belt conveyors for bulk handling applications.

Cement is the basic ingredient of construction and the most widely used construction material. Its manufacturing includes extraction, proportioning, grinding,

International journal of advanced scientific and technical research Issue 4 volume 1, January-February 2014 Available online on ...

Figure 2: The integrated cement plants and standalone cement grinding plants in the UAE in 2014, colour-coded by installed integrated cement production capacity in ...

Loesche has provided a LM 56 3+3 CS vertical roller mill to Attock Cement Pakistan Ltd, for the grinding of cement clinker. The new mill will be used in the new line ...

The production process for cement consists of drying, grinding and mixing limestone and additives like bauxite and iron ore into a powder known as "raw meal".

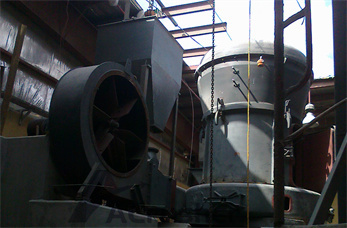

Full Vent System Clinker Collector I.D.Fan Gypsum Separator Collector To Product Storage Mill Collector O-Sepa Separator Primar Air Secondary Air Finish Mill Mill

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

The origin of OCL was seeded in the time that signaled India's independence. A dream unleashed. A blue print of growth was ...

Chemical Considerations. The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the ...

Commercial Food and Cheese Chopping and Cutting Equipment. Schier Company Inc. has a wide variety of cutters available including grinders, shredders, flakers and ...

•Availability of funds 4 CASE STUDY Holtec had carried out a plant operations audit in a dry process cement plant operating at a capacity of about 3,350 tpd clinker.

How is cement manufactured? Learn cement manufacturing process thoroughly.

Inside a (stationary!) cement mill. The part-ground clinker and steel grinding media are clearly visible. (Picture courtesy Castle Cement).

FL wins cement grinding plant contract in Nepal FL has signed a contract with Nepal Shalimar Private Limited for engineering, procurement and supply .

WhatsApp)

WhatsApp)